Batten Seal Installation, Maintenance, and Refurbishment for Walk-In Cooler & Freezers

Batten down the hatches of your cold storage equipment with custom Insulated Batten Seals or Batten Strips! Destroy humidity issues by using Batten Seals or Batten Strips.

Batten Strips can provide an extra seal for your old walk-in box. Or Batten Seals can be installed to achieve additional protection to make your old walk-in look like a brand-new refrigerator or freezer ready to fight humidity for years to come!

Whether out of necessity, or for preventative maintenance, Batten Seals are a valuable product for many clients of the Cold Door Medics at Gina Marie Refrigerator Doors.

Panel Seals and Vapor Sealing are other terms which describe these essential cold storage panels for walk-in cold storage boxes.

- Insulated cold storage panel consists of a 4 to 6-inch-thick Metal and Foam sandwich that is extruded in 44 to 46-inch-wide, and found in multiple heights and lengths

- In walk-in boxes, panels are cam-locked together to create the cold storage room or cold storage environment

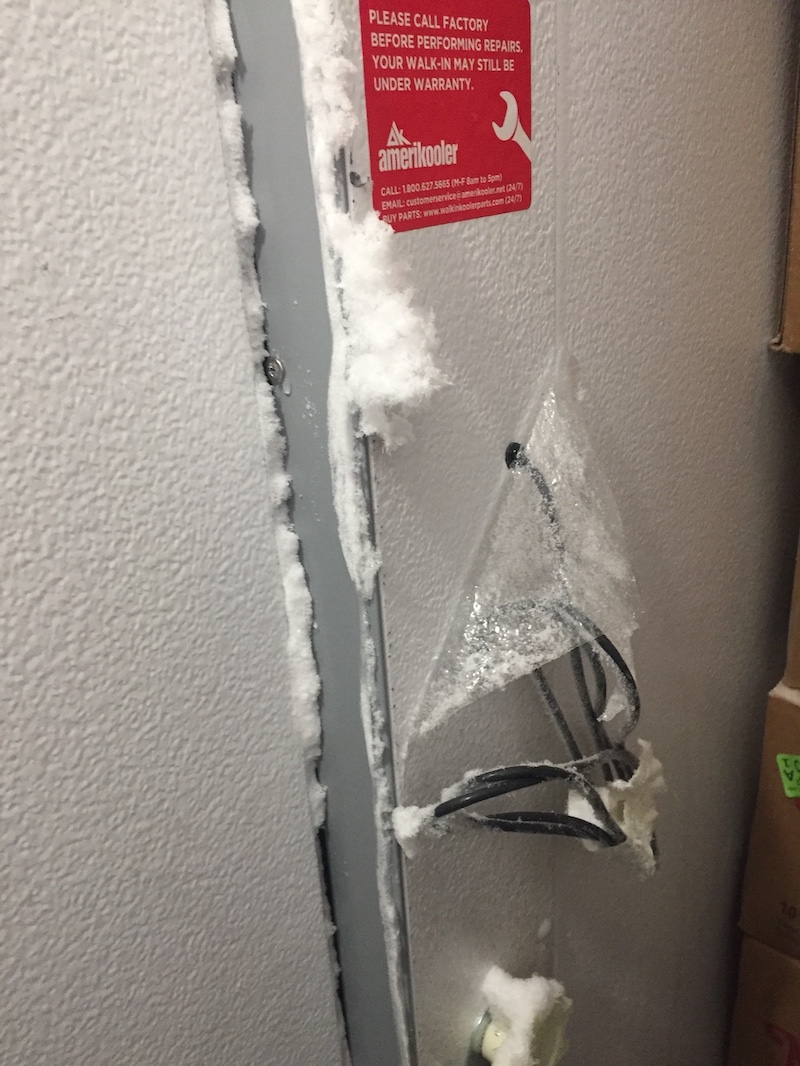

- Insulated Batten Seals are installed on these cam-lock seams to seal, refurbish, and modernize the interior and/or exterior of walk-in coolers and freezers

- Cold Storage Medics at Gina Marie Refrigerator Doors will seal walk-in boxes

- The Insulated Batten Seal is for the walk-in box interior and exterior

- Insulate the interior of walk-in cold storage rooms

- Sealing services for walk-in freezer and cooler of interior or exterior panel seams

Batten seals and strips fight humidity

The professional crew of Cold Door Medics at Gina Marie Refrigerator Doors can install new cold storage equipment, or repair refrigerators, freezers, and other cold storage systems. Our repair service breathes new life into old equipment that may hold potential for decreased efficiency.

Budget is impacted when old equipment is not serviced and falls out of energy efficiency! What’s more, ice build-up, condensation, pooling water, mold, and mildew are all possible when equipment is not serviced. These issues can lead to damaged products and damaged lives if there is a slip-and-fall!

Refrigeration merchandisers and cold storage walk-ins are always under a vacuum—pulling warmer outside air into and inside the fixture. So, humidity always finds a way into the cold storage vessel!

Understanding humidity

- Humidity is the ever-present concentration of water vapor in the air

- When a panel seal is faulty, warm air particles from the outside area are drawn inside

- This moisture is condensed, and in-turn increases humidity inside the cold storage environment

- Humidity forces equipment to work harder drawing more power and increasing energy costs

- Humidity also promotes mold and mildew growth

- Indicators of humidity include:

-

- Frost and/or Ice build-up—which impact how customers or employees see products in cold storage environments

-

- Pooling water—which is a slip-and-fall hazard

-

- Visible mist

- Stored products become wet—which leads to damage and loss